Introduction

In recent years, the automotive industry has seen a significant shift towards lightweighting technologies. The quest for improved vehicle performance, fuel efficiency, and reduced emissions has led to groundbreaking innovations in materials and manufacturing processes. One of the most prominent lightweighting solutions is carbon fiber, which offers unparalleled strength-to-weight ratio. However, carbon fiber is just the tip of the iceberg. Today, we will explore the latest lightweighting innovations that go beyond carbon fiber and their impact on the automotive industry.

The Rise of Carbon Fiber

Carbon fiber has gained immense popularity for its exceptional properties that make it ideal for lightweighting. With a weight only a fraction of steel or aluminum, carbon fiber offers comparable or even superior strength. This advanced material is manufactured through a process involving weaving carbon filaments into a fabric, which is then reinforced with a resin matrix. The resulting composite is incredibly lightweight and rigid, making it an excellent choice for various automotive applications.

Carbon Fiber in Vehicle Construction

To leverage the benefits of carbon fiber, automotive manufacturers have started incorporating it into vehicle construction. Traditionally, steel has been the go-to material for car frames due to its high strength. However, steel is considerably heavier compared to carbon fiber. By integrating carbon fiber into the chassis and body structure, carmakers can significantly reduce the weight of vehicles without compromising safety.

Lightweighting and Performance

The reduction in vehicle weight achieved through carbon fiber lightweighting has a tremendous impact on performance. Lighter cars require less energy to accelerate and decelerate, resulting in improved acceleration and braking. Additionally, the reduced weight allows for better maneuverability and handling, enhancing the overall driving experience. Furthermore, the weight reduction contributes to better fuel efficiency, reducing environmental impact and operating costs.

Beyond Carbon Fiber

While carbon fiber is undoubtedly a game-changer, ongoing research and development in lightweighting have introduced several other innovative materials and technologies. Let’s explore some of these advancements:

Aluminum Alloys

Aluminum alloys have long been used in the automotive industry due to their lighter weight compared to steel. However, recent advancements in aluminum alloy manufacturing have opened up new possibilities for lighter and stronger components. The introduction of high-strength aluminum alloys, such as the 7000 series, has allowed for the production of lightweight structural parts without sacrificing strength.

Magnesium

Magnesium is another promising lightweight material that offers a weight-saving potential of up to 75% compared to steel. Although magnesium is not as widely used as carbon fiber or aluminum, it has excellent properties such as high strength-to-weight ratio and good heat dissipation. As research and manufacturing techniques improve, we can expect to see more applications of magnesium in automotive lightweighting.

Polymer Composites

Polymer composites, similar to carbon fiber composites, consist of reinforced fibers embedded in a polymer matrix. These composites offer a unique combination of lightweight properties, high strength, flexibility, and design versatility. By utilizing advanced manufacturing processes like 3D printing, polymer composites can be tailored to specific applications, further optimizing weight reduction and performance.

Advanced Steel Alloys

Steel, a long-standing staple in the automotive industry, is not to be overlooked in the lightweighting game. Recent advancements in steel manufacturing technology have led to the development of advanced high-strength steels (AHSS). These new steel alloys offer exceptional strength and elongation properties while remaining lightweight. AHSS enables car manufacturers to achieve substantial weight reductions while maintaining structural integrity.

The Future of Lightweighting

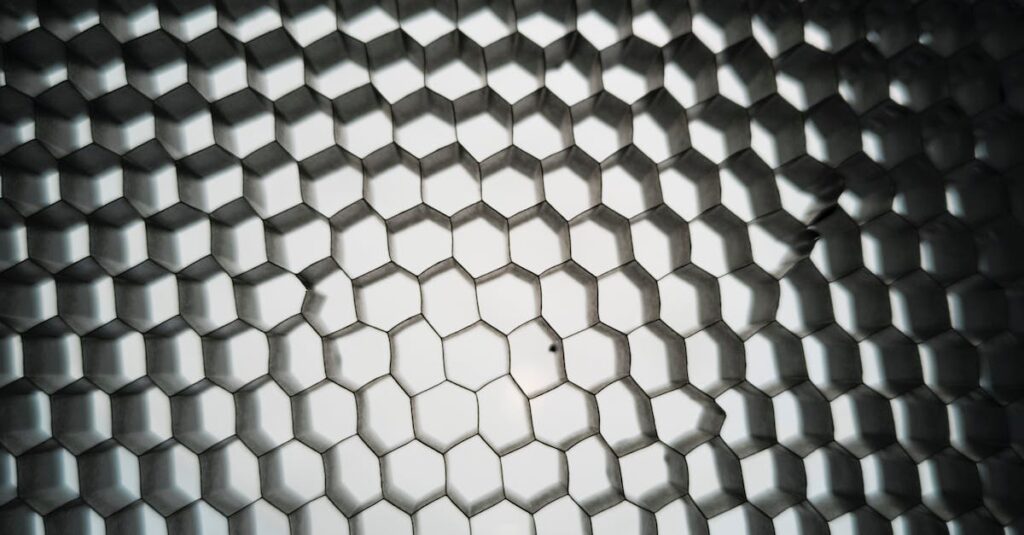

As automotive technology continues to advance, so does the pursuit of lightweighting solutions. Future innovations may include materials such as graphene, which holds promise due to its outstanding mechanical properties. Graphene is a single layer of carbon atoms arranged in a hexagonal lattice, offering incredible strength, lightness, and electrical conductivity. Integrating graphene into vehicles could revolutionize lightweighting, leading to even greater performance and efficiency gains.

Summary

The automotive industry is constantly evolving, and lightweighting innovations play a vital role in shaping its future. Carbon fiber has paved the way for lightweight materials, but ongoing research and development have introduced alternative solutions such as aluminum alloys, magnesium, polymer composites, and advanced steel alloys. These materials collectively contribute to improved vehicle performance, fuel efficiency, and reduced environmental impact. As technology progresses, the future holds even more exciting possibilities, with materials like graphene pushing the boundaries of lightweighting innovation in the automotive sector.